In the manufacturing of apparel, Sampling is crucial to the production of clothing that entices consumers. This is a characteristic of consumers that if they are happy with the samples of garments, they are more likely to order. Additionally, from the consumer’s perspective, in order to ensure the quality of fabric derived from the supply chain, the consumers ensure that the products satisfy the requirements, design, and material quality while also fitting into the order of brands.

The buyers and manufacturers consistently communicate with the suppliers during every phase of development, from creation to completion of a finished product. At different phases of the product’s creation, the development of samples is pivotal. This procedure for developing samples is standard and is known by different names. Each sample has its own unique objective that is accomplished in different stages of development.

As previously mentioned, there are multiple varieties of clothing samples. As a clothing sample maker and manufacturer of clothes, it’s crucial to recognize the distinction between all and the significance of each type of Sample. Understanding each type can help you decide which type of Sampling is most beneficial to you.

The purpose of Garment Sampling

The primary goal of garment samples is to achieve the brand’s desired product quality that satisfies their needs and specifications. The sample is made in a factory that will produce large quantities of the product that will be distributed to customers or brands in order to have a concrete idea of what sort of product they will receive in bulk.

The technic pack is another visual file that is sent to you prior to the production of the garment’s sample, this technic pack contains all of the information regarding the clothing product you’re receiving. Additionally, if the sample product is transferred to the customer, and they believe that there are significant changes in the market or brand, they can inform the manufacturers of the changes.

The alterations will be made to the ultimate product sample, following the brands and business’s requirements. The process of sampling garments is helpful in avoiding confusion and problems.

Before we discuss the different types of garment samples, I want to inform you about another significant aspect: the stages of garment sampling.

Sampling Steps in the Garment Industry

When manufacturing clothes in a room or factory, there are typically three stages of product development or sample development. The first stage is the planning phase. In this phase, all things from design to pattern creation are scrutinized thoroughly. This leads us to the next step, which is the evaluation phase. In this phase, the garment is complete and ready for finalizing costs.

This leads us to the next step and final goal of the production process. After the sample’s approval, the product is dedicated to production. After the manufacturing process, when the completed product has been received, you must re-examine the samples and the completed product itself to make sure the quality of the product is maintained and if it meets the requirements.

This phase of the sample checks for quality andiqueness, it will make your customer happy as well as make the brand stand out due to its superior quality and offerings.

Now that we have a comprehensive understanding of all of the stages of product development, it’s ideal to find out what different types of garments have. Let’s begin:

Different varieties of garment samples

Several varieties of Sampling are employed during the development process of a product. Here is a list of all of them together and their definitions below:

First Sample/ Proto Sample

This is the first instance of a design sample’s development via the concept of design or via the design sketch itself. This phase typically involves matching the quality of the fabric, its type, and its weight.

During the developmental process of the proto sample, the actual fabric that is being employed is not accessible. The first sample is only created in one size, and the number of initial samples is based on the customer’s preferences.

The most effective practice is to create three samples. Two of the samples should be delegated to the customer to review. The customer should send back 1 sample to the manufacturer, while the 3rd sample can be used as the manufacturer’s counter sample of proto.

If any third parties are involved in the creation of the sample or in the manufacturing process, there should be an extra sample.

Samples that are appropriate

The sample’s fit is another critical component of apparel design. The process of fitting the sample involves a sheet of paper that contains all of the measurements and specifications for design. This spec sheet is employed to develop a sample that meets the demands and requirements of the customer.

As is documented in the name, the primary purpose of this sample is to assess if the sample is appropriate for the human model or not. The measurements employed over the sample’s fit are derived from the height and stipulations of the specifications sheets. Similarly, the sample’s fit is also altered for the middle sized object in the first sample. And two or three samples that fit are created.

Other than that, the frequency of re- submissions for the successful sample is higher.

Sample Size

The purpose of the Size set is to assess the diversity of sizes in a selection of different categories. Typically, developed samples are intended for use with small, medium and large sized collections, according to customer requests regarding manufacturing.

During this developmental phase, if the production team learns that some of the pieces don’t fit properly, they will make alterations to the patterning to achieve a proper fit that satisfies the requirements.

These samples are created using the selected fabric from the client. Another material can be employed in instances where there is no actual fabric available.

Sample salesman (SMS)

The SMS or salesman sample is derived from genuine and original materials. These samples are intended to exhibit the retailers. The primary goal of introducing the product to the retail market is to predict sales and volume of orders. These are also referred to as marketing samples, because these are displayed to the customers.

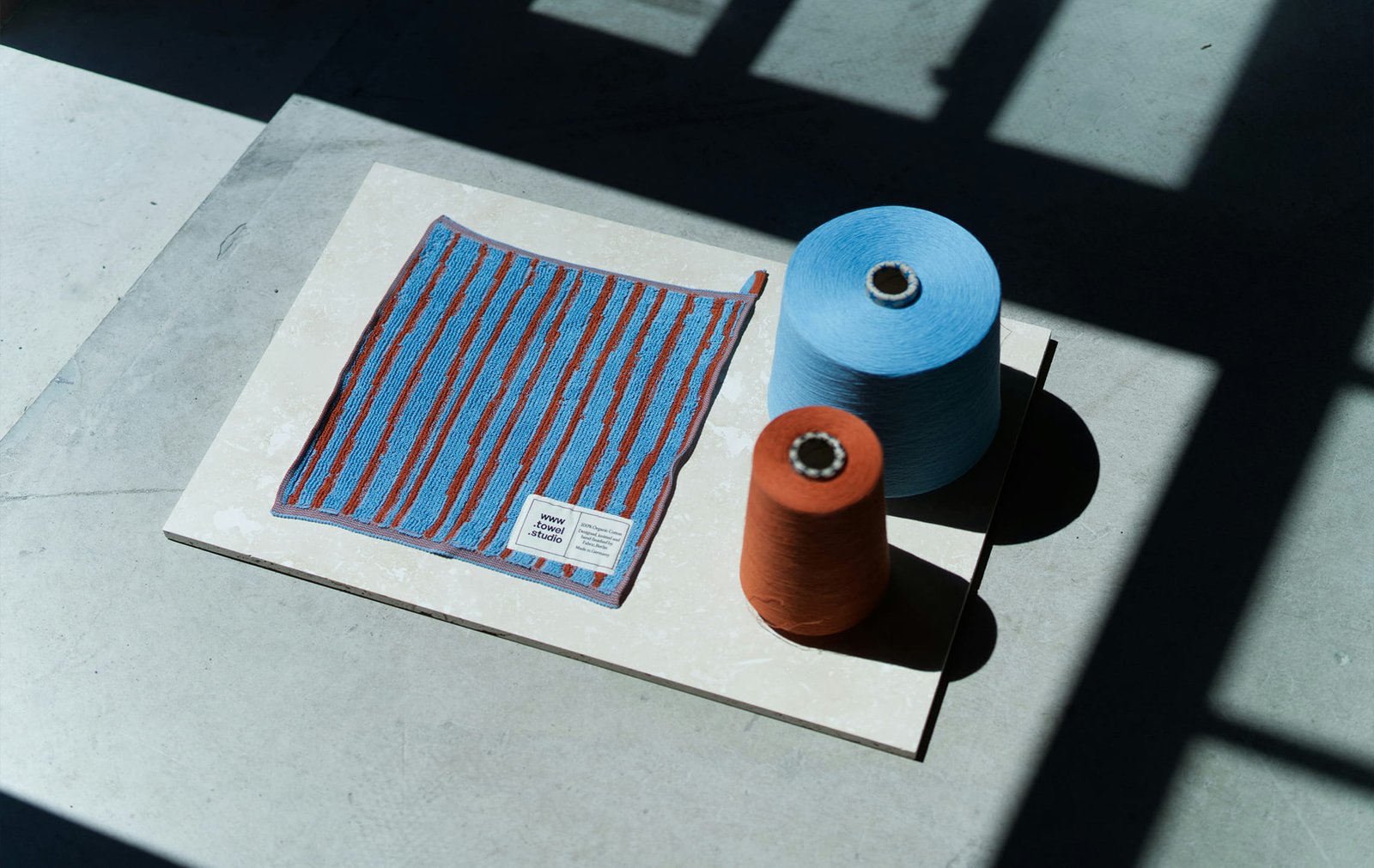

The Sample Photography

As is documented in the name, photo-shooting sampling is the process of taking a photograph and using it to promote products on billboards or to build a product catalog for e-commerce websites. The images of the dress are derived from the model’s or the dress’s alone. The photoshoot sample is frequent in fashion-related samples.

Pre-production Sample

The samples prior to production are composed of utilizing the actual fabric. These are also referred to as pp samples that are manufactured in the factory, and all samples are developed in the sample room.

The preproduction sample is made with all of the specifications, design requirements, measurements, embroidery, and other pertinent details. The pp sampling procedure is similar to a factory inspection that checks if the company can continue with the bulk production of a product only if the brand or client is happy with the sample.

Gold Sample sealed

When the sample is officially approved for mass production, it can be called a gold-sealed sample if the consumer has sealed the pp sample. The buyer uses a sealant that cannot be removed without destroying the sample.

A unique code is assigned to each sample by the consumer in order to distinguish it from other samples. The sample is confined to avoid being manipulated by people who have authorization.

Opposition Samples

When creating a prototype that will be sent to clients and brands for approval, the manufacturer will make two or more additional samples that will be used as a reference. These samples are referred to as counter examples. These samples are similar to the original products that can be used as a guide in the event that the authorized samples are not available.

Sample Shipment

The sample that is ready for shipment has all of the information necessary to package it, including the packaging details, measurements, and all of the associated information that will be displayed in stores.

The facility produces three samples for shipment, one for the consumer, one for the reference of the factory, and one for the merchant who shops for houses.

The facility maintains the sample as a shipment to the buyer, this is used as a guide to create larger production or make alterations if desired by the customer.

GPT Sample

GPT advocates the use of Garment’s Performance Test. In this style of Sampling, one of the parts of the bulk production is selected and transported to the testing laboratory to assess the quality of the Garment. In GPT, the test of garment performance has included experiments that attempted to measure strength, seams that slip, buttons that pull, chemical tests on metals, print quality, and coloring.

The list tests are conducted in the laboratory to assess the effects of the situation from the buyer’s and customer’s perspectives. Typically, brands and companies don’t require sample reports on GPT. Occasionally, they require documentation of a specific desired attribute.

Development Sample

These are the samples that are produced after the bulk production is approved. The first sample, its size and composition, is also considered the growth sample.

Sealed Sample/Red Tag Sample

The sealed sample and the redtag sample are both identical. The red tag on the products that are being sold indicates the ultimate product, which is ready to be sold after the mass production. A red label is placed on the sealed sample.

Sample Digital Cloth

Any clothing sample that is created using computer software or that visualizes the 3D shape of the garment is referred to as a digital garment sample. In the digital sample of clothing, the brand or company can directly observe and digitalize all of the information regarding fabric composition, pressure points, measurements, and fitting guidelines.

Technology has evolved to the present state. For instance, the majority of manufacturers utilize digital samples of clothing to reduce the time needed to approve and process. Additionally, the customer can alter the product by commenting on the sample’s display, and the user can be considered a physical representation of the sample.

Why do you need to have samples of garments in your line of clothing?

With a sample maker that creates clothing, you can ask him to create a sample product for your brand that will help you determine if the sample maker is capable of completing your requirements. Or if the sample’s results differ from what you expected, you need to reconsider how to alter your plan before you approve the production of large quantities.

It’s common for the result of a different product than what you originally intended. In this situation, you should address this. You must have a concept of what adjustments you need to make in order to create a dependable, safe, and durable sample that will meet your expectations. Additionally, the process of making samples increases your control over the system used to assemble or create patterns.

Occasionally, the sample is incorrect, and the error is derived from the manufacturer’s end due to miscommunication or mishearing. In this instance, you must ask the manufacturer to re-run the sample test without mistakes. Some professionals will acknowledge their errors and provide a sample for you. However, you must pay attention from the first location, this decreases the likelihood of mistakes.

Remember that if you receive services from a sample creator, you have all rights to demand alterations or changes, unless you believe that you received the perfect product in the original form.

Conclusion

The process of developing a sample is dependent on the specifications and desires of the customer. The demands of the customer are changing. Some customers want to see samples of the final product before the production sample, while other designers require a salesman sample instead of a photohoot sample. Additionally, some buyers fail to demand top samples.